Technologies

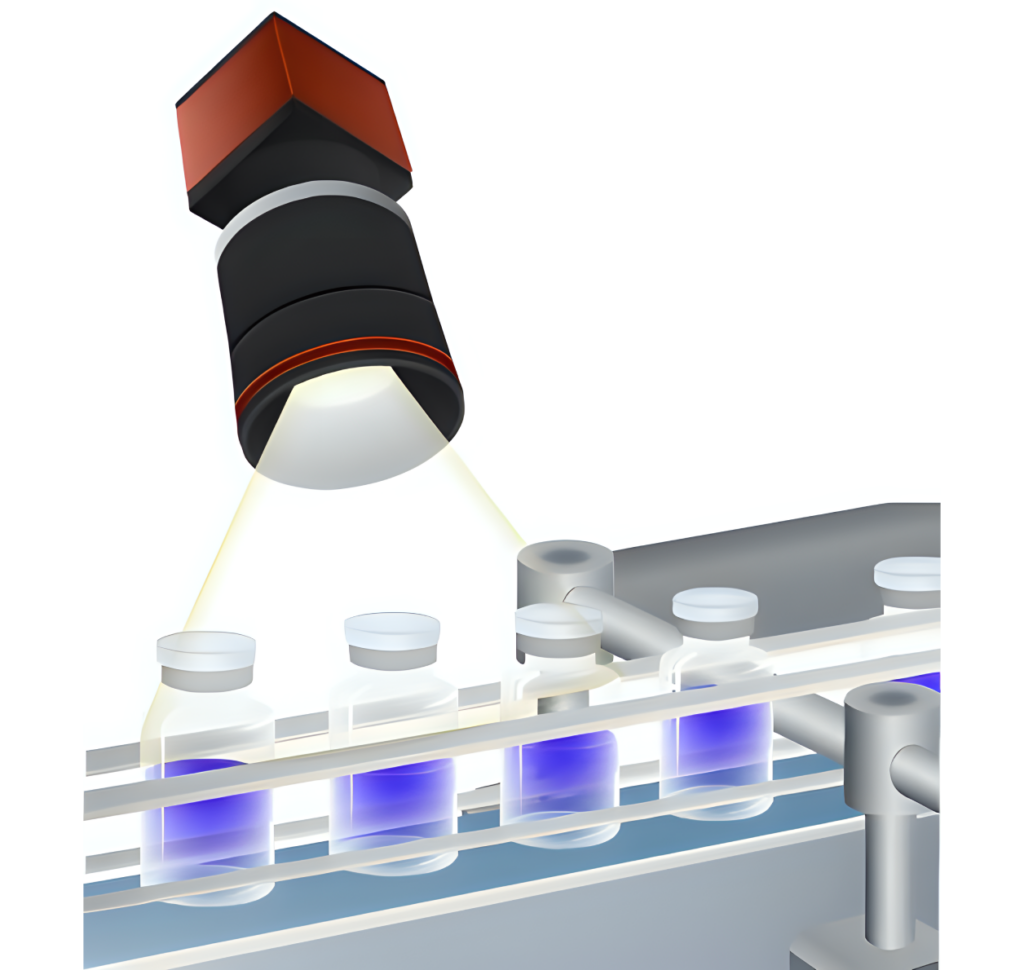

Polarized light visual inspection systems

Visual inspection of production processes, goes beyond normal quality control and particle counting.

Tensions in the container, scratches, abrasion, pressure in the container- all becomes visible. And so, it can be optimized and controlled: transport processes of vials and other transparent containers in pharmaceutical manufacturing.

Technologies

Visual inspection with polarized light, goes beyond normal quality control and particle counting.

Tensions in the container material, scratches, abrasion during line transport and movement- all become visible.

Production process in pharmaceutical manufacturing (sterile fill & finish) can be optiomized directly at the line.

We offer rental equipment, training or lab analysis at our premises.

Exploring solutions

Towards a better future

through research

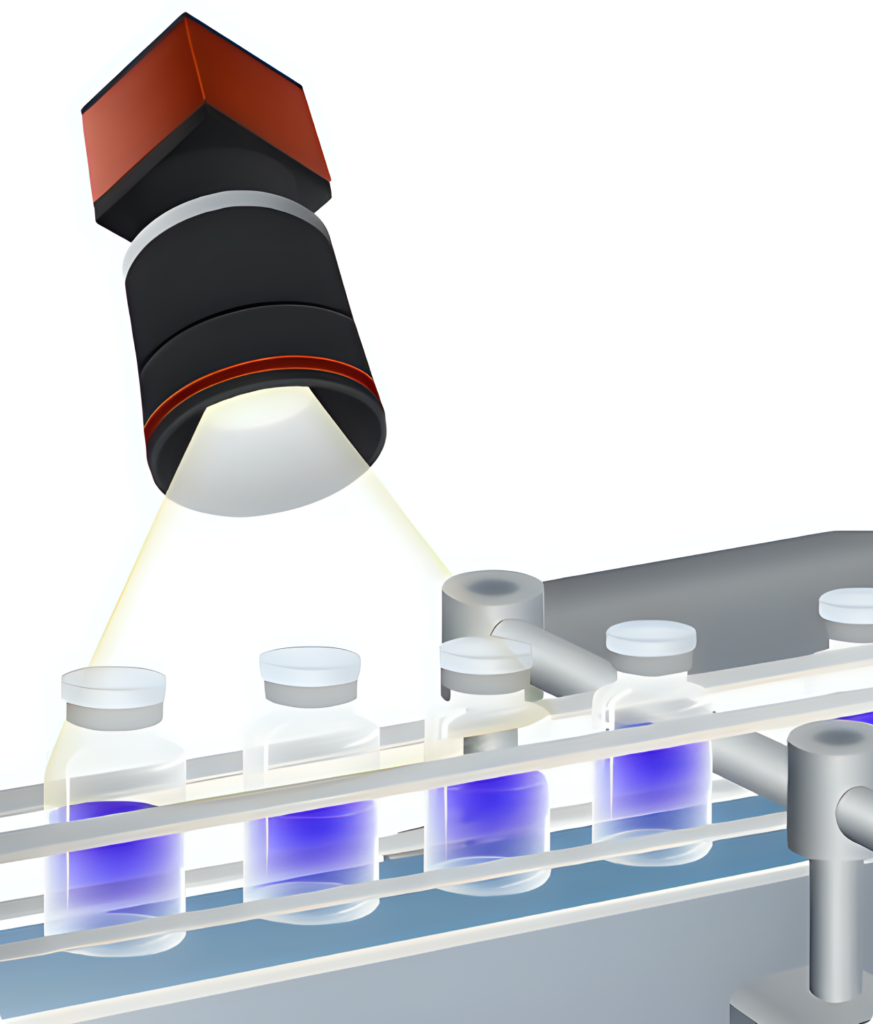

Our devices and equipment can be transported easily. After initial training, you use our cameras and detectors. Live improvements at the production line are possible.

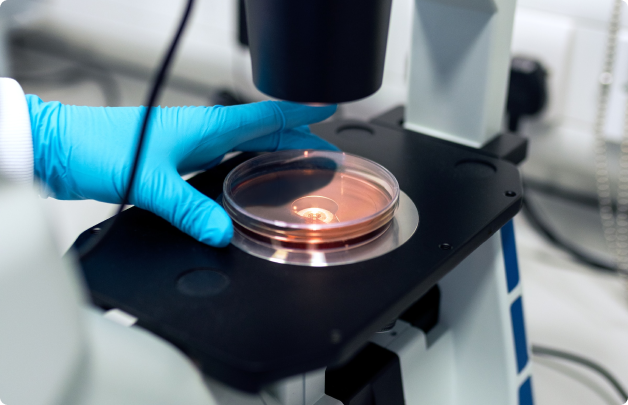

Alternatively, we analyze outturn samples under lab conditions.

Solution

Revolutionizing detection technology:

The new polarized light detection systems

We lease our fully equipped polarized light system . Applications directly at the manufacturing line, become now accessible.

Certainly we train before and instruct core users.

Alternatively, we analyse samples from typical production situations, in our lab.

Contact us for your specific application.

Your advantage

The advantages of choosing this option

- Complete measurement system for your production line diagnosis.

- Time based prizing.

- Measures material properties directly.