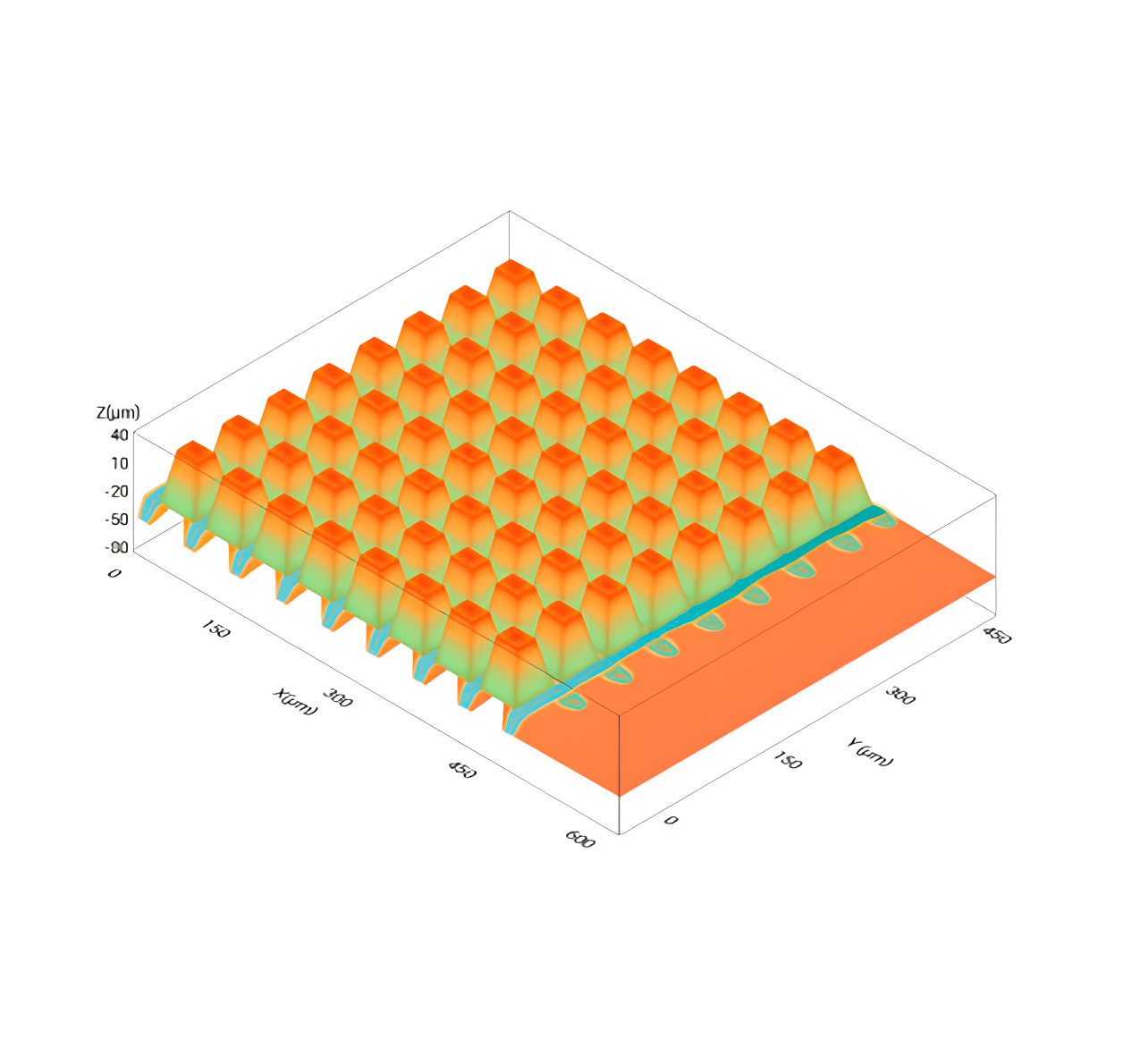

We structure surfaces with various laser systems. The changed topology can be as fine as an optical grating (in the nanometer range) or “larger” in the micrometer range. Such structures manipulate light waves but also liquid flow and wettability of surfaces.

Applications range from improved cell adherence for implants to completely non-wetting surfaces, with extremely low particle and cell adsorption.e

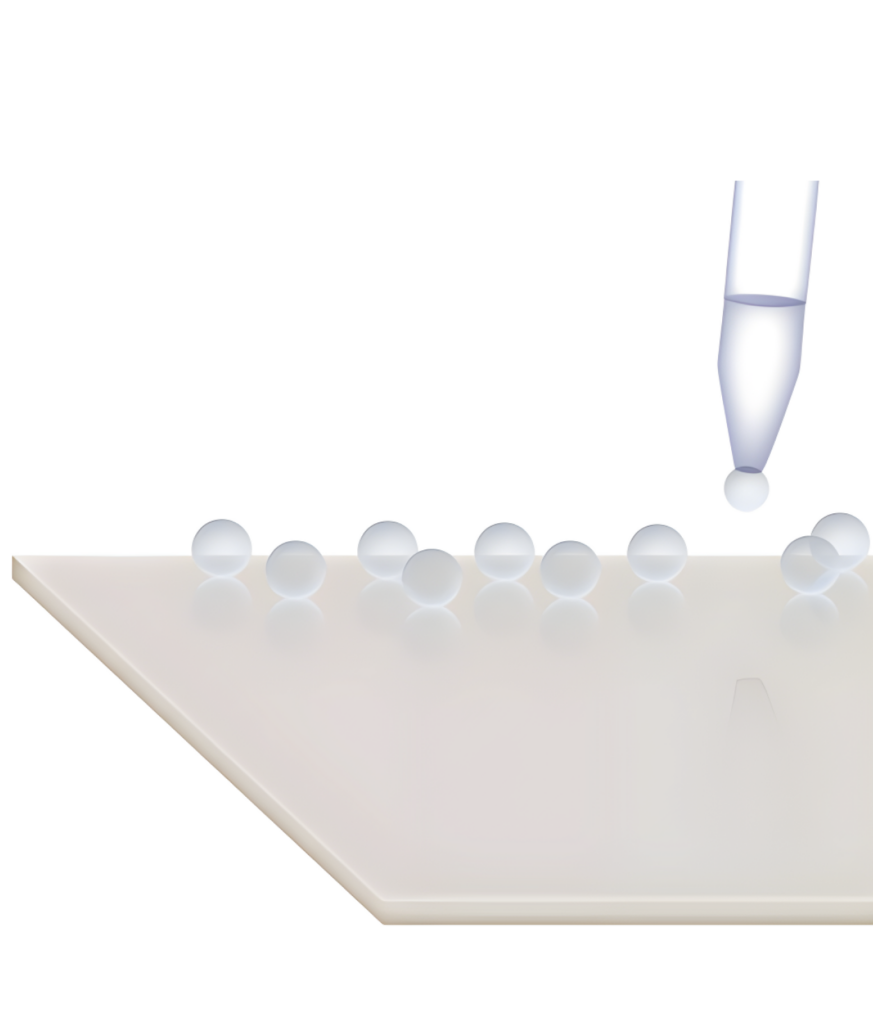

We laser-structure surfaces that they become super- hydrophobic.

No liquid adhesion. No particle adhesion. No cell adhesion.

Share your thoughts and challenges.